Knowing about different types of compressors and their usage helps you with better understanding the function of refrigeration systems. Compressor has a vital role in refrigeration cycle and is in fact the heart of the refrigeration system.

The role of compressor is raising the pressure and temperature of the refrigerant gas to get ready for entering the condenser and turning into liquid.

Although the main role of compressor is the same in all refrigeration systems, but there are different types of them that pressurize the refrigerant in different ways. Here we are going to introduce you the compressor types and their advantages and disadvantages.

There are five types of compressors in refrigeration systems:

- Rotary compressors

- Scroll compressors

- Screw compressors

- Reciprocating compressors

- Centrifugal compressors

Rotary compressors in refrigeration system

Rotary compressor is a kind of positive displacement machine of rotating type. The suction and compression of the refrigerant gas is done by 360° rotation of rotors. The refrigerant is pressurized by this rotation and thrown out of the compressor.

Tip: rotary compressors are suitable for regions with high pressure air and are mostly used in low capacity house refrigerator and air conditioners.

Simple construction, low energy consumption and little noise are some characteristics of rotary compressors that have made them favorable for producers of house air conditioners.

Note: rotary compressors are the only type of compressor that can be removed from the appliance, taken to the repairman and reassemble again.

Advantages:

- Less moving parts, little noise

- Low energy consumption

- Simple construction

Disadvantages:

- Low lifespan

- Low efficiency specially in polluted environments

- Limited capacity (between 7000 to 36000 BTU)

Scroll compressors in refrigeration system

A scroll compressor consists of 2 spiral scrolls assembled at a relative angle of 180°C. One scroll is fixed, the other orbits. This rotation compresses the refrigerant gas and raises its temperature and pressure. The main parts of a scroll compressor are:

- The fixed scroll

- The orbiting scroll

- Crankshaft and bearing

- Rotor and stator

- Oil pump

- Suction and discharge pipe

- Compression chamber

The scroll compressor functions in three main stages:

- Refrigerant suction

- Refrigerant compression

- Refrigerant discharge

The spiral scrolls have the most important role during these three stages.

Tip: scroll compressors can be used in food and fruit refrigeration, truck transportation, vacuum pumps and residential and small to medium commercial air conditioners

Advantages:

- High efficiency in comparison to other compressors

- Low noise and vibration due to absence of several moving parts

- Simple construction and use

- Long lifespan

Disadvantages:

- Not repairable

- Limited capacity for using in large chillers

Screw compressors in refrigeration system

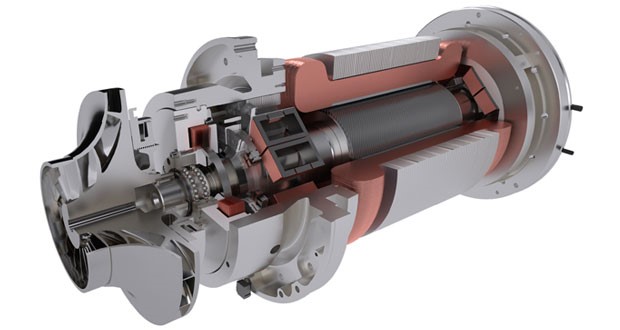

Screw compressors use rotary movement to compress the refrigerant gas. These compressors have a set of male and female rotors to trap the gas between them. The male rotor has convex lobes and the female rotor has concave cavities. So they mesh together without touching to achieve compression.

Advantages:

- Having various capacities

- Repairable

- Long lifespan without any efficiency loss

Disadvantages:

- So noisy

- High weight

- Occupying more space

Reciprocating compressors in refrigeration system

Reciprocating compressors have a design similar to combustion engines. They are one of the positive displacement compressors and function in 3 stages:

- In the first stage, piston moves downward to suck the low-pressure refrigerant into the cylinder through an inlet valve.

- In the second stage, the piston moves back upwards, the inlet valve closes, the space in the cylinder decreases and refrigerant is compressed.

- In the third stage, the pressurized refrigerant opens the discharge valve to expel and the cycle repeats again.

Tip: reciprocating compressors can be designed for a small capacity or a high capacity of hundreds of tones.

Advantages:

- Long lifespan

- Various capacities

- No oil is needed

- Low initial cost in comparison to other compressors

Disadvantages:

- Low efficiency

- Very loud

- High amount of vibration

- High maintenance cost

Centrifugal compressors in refrigeration system

Centrifugal compressors are among dynamic compressors. They pressurize the refrigerant by forcing it through a rotating impeller. The impeller spins the refrigerant at an increasing speed to generate kinetic energy in order to pressurize the refrigerant by passing through a diffuser.

Advantages:

- Having the largest capacity

- No oil is needed

- The least vibration

Disadvantages:

- High initial investment cost

If you need more information about refrigeration systems of cold room and chillers, you can watch refrigeration training course in HelloTechnic website. Our experts will teach you everything you need about cold rooms and chillers using films and animations.